As a leading supplier of twin-screw extruders and accessories in China, Kerke provides customers with comprehensive accessory sales services covering all categories, processes, and cycles through its deep technological accumulation and global service network. We have built the most comprehensive product library of twin-screw extruder accessories in the industry, covering core components, vulnerable parts, auxiliary devices, and customized components.

Original accessories

Covering core transmission system components, barrel components, intelligent auxiliary devices, as well as vulnerable parts and consumables.

Customization of accessories

The production needs of customers vary greatly, so we offer customized services for extruder accessories that are suitable for different brands of extruders.

We can independently produce and assemble accessories, and strictly control the quality of every accessory,

global service, quick response, after-sales available.

كيركي

Free Spare Parts List

If you buy a Kerke extruder, you will receive the following quantity of free accessories, all of which will be shipped together with the machine. At the same time, we also recommend purchasing more related accessories for future use, which we will sell to new customers at the lowest price.

| اسم | Quantity |

|---|---|

| Screw elements | ~300mm |

| Pelletizer kinfe | 2 sets |

| Solid state relay | 2 pcs |

| Solenoid valve | 1 pc |

| Temperature control meter | 1 pc |

| Thermocouple | 2 pcs |

| Hardware tools box | 1 unit |

| Framework oil seal | 4 pcs |

| Nylon pins | 6 pcs |

| O ring | 2 pcs |

Accessories and Price

We can provide the most complete accessories for extruders, so you don’t have to worry about not being able to purchase qualified accessories in your production and operation after purchasing the machine.

If you are using other models of extruders or different brands of extruders, please contact our engineers directly for customized accessories.

Accessories Display

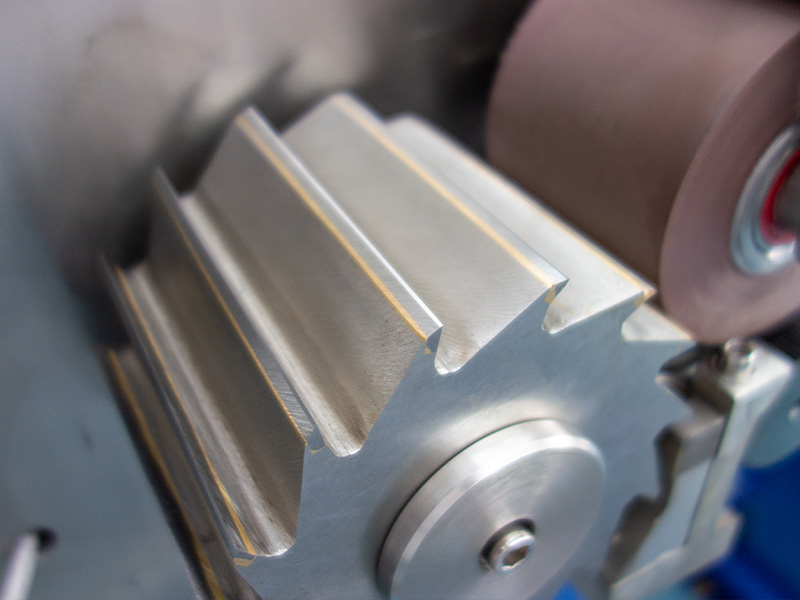

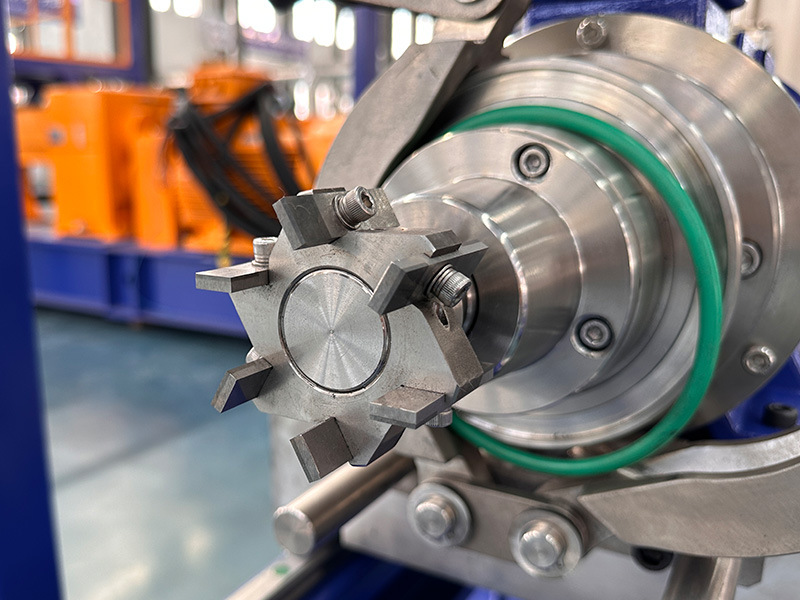

Cutter Knife

Used to precisely cut extruded plastic strips or sheets according to specified dimensions for subsequent processing or packaging.

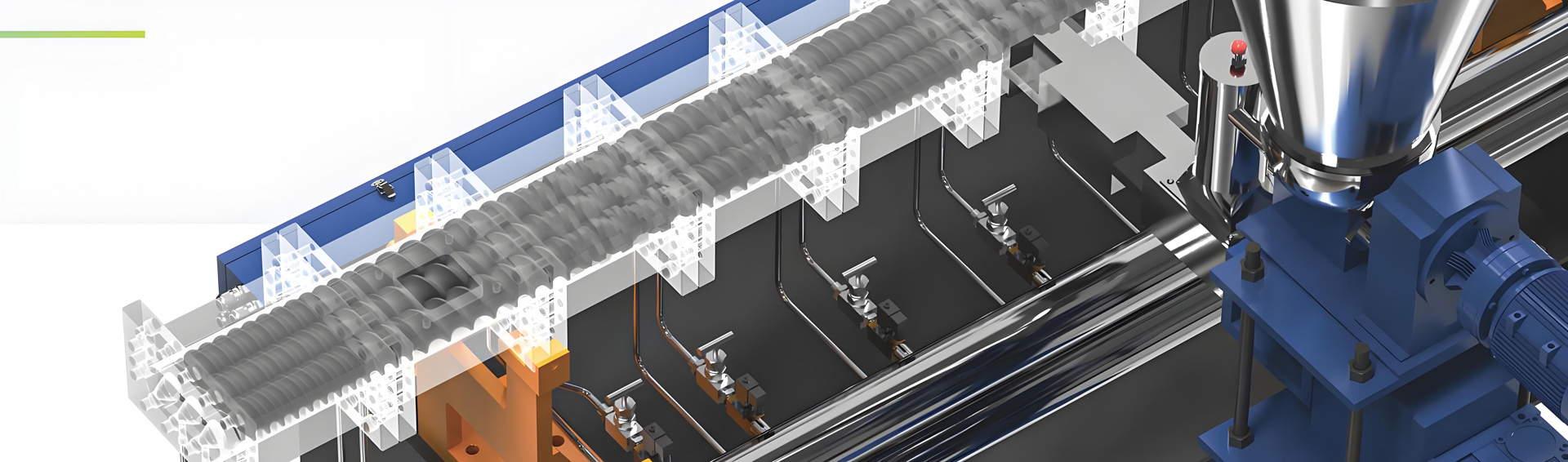

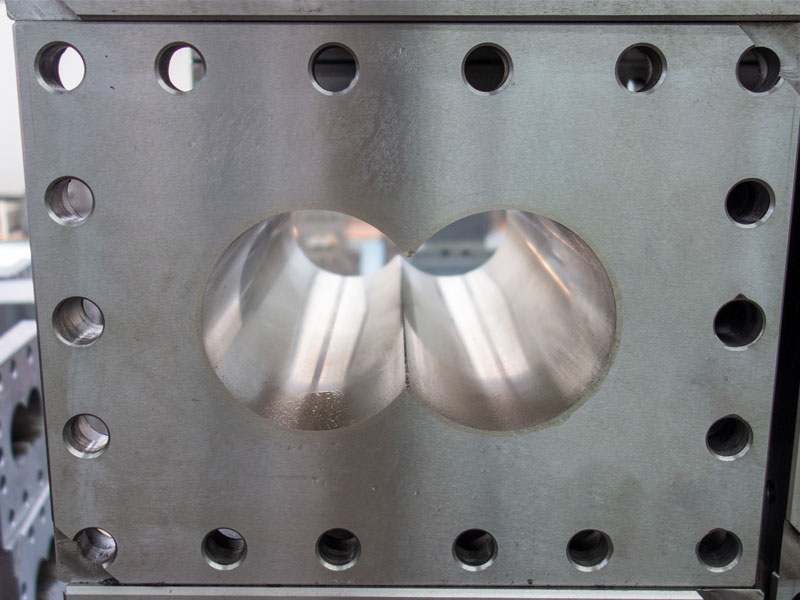

Barrel

Cooperating with screws to transport, heat, melt, and plasticize plastics, providing processing space for materials, is a key component.

Underwater Pelletizer

Quickly cool and cut the extruded high-temperature plastic melt into uniform particles with a smooth surface in an underwater environment.

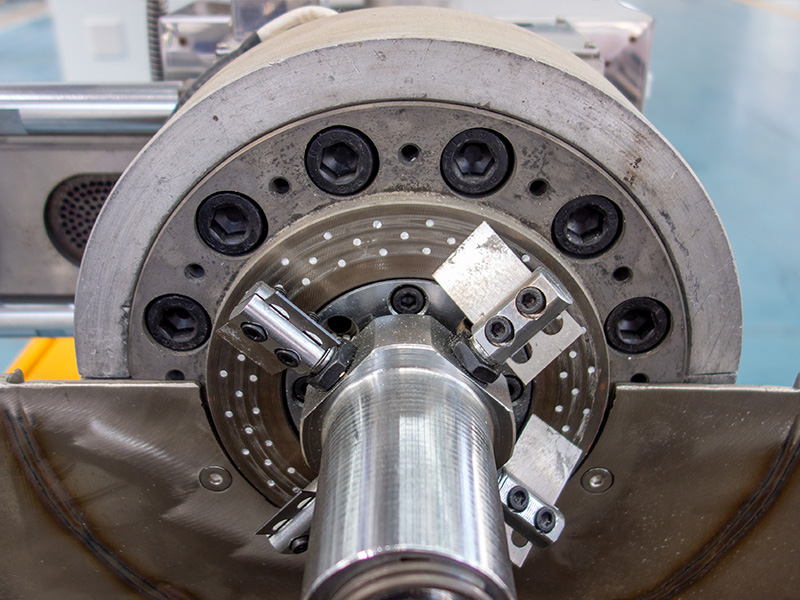

Shaft

As a transmission component, it provides power transmission for the screw to ensure stable operation of all components of the equipment.

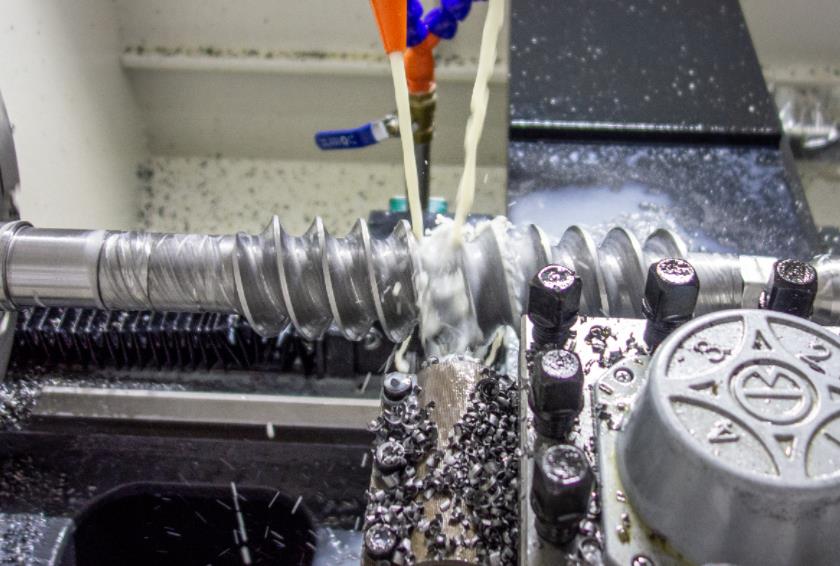

عنصر المسمار

The component unit of the screw can achieve functions such as conveying, compressing, mixing, and homogenization of plastics.

Die Face Cutter

Directly hot cutting the extruded plastic melt at the mold outlet is commonly used to produce temperature sensitive plastic particles.

اتصل بنا

إذا كنت مهتمًا بشركتنا وأجهزتنا، فلا تتردد في الاتصال بمهندس مبيعات شركة kerke. وسنتواصل معك في أقرب وقت ممكن.