Compounding Extruder

Here you can find different extruders for different applications, we have parallel twin screw extruders, three screws extruders, laboratory extruders, double stage extruders, single screw extruders etc

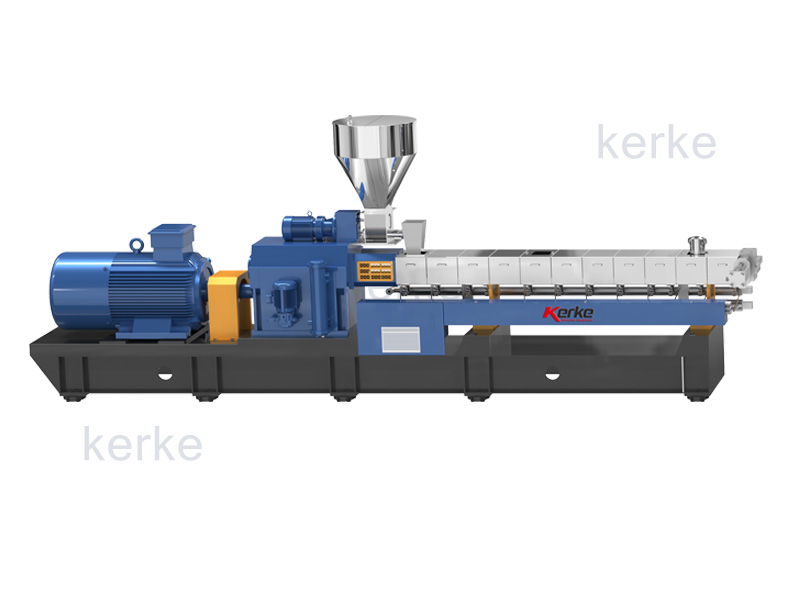

Compounding Extruder (Co-rotating Parallel)

Are you looking for a good supplier who is professional in co-rotating parallel compounding extruders? Kerke, with over 13 years of experience, provides not only high-quality compounding extruders but also good prices and service.

Plastic Sheet Extrusion Line

- One Step: We use a twin screw extruder which can make compounding and sheet extruder in one step, not like the single extruder, you should make compounded granules, then make the sheet

- Energy Saving: Because we use a one-step sheet-making process, it can save much energy.

- Cost Saving: You can save more money on machine and materials purchasing.

PVB Film Production Line

You can find some PVB film production line manufacturers in China, but we can provide turnkey solutions for PVB film production lines, we provide from formula to end film and promise if the end film can not meet your requirement, we will refund all your payment and pay extra money (US$20000) to you as compensation.

PET/R-PET Sheet Production Line

Twin screw extruder has unique merits to the process of polyester resins. Polyester is very vulnerable to thermal decomposition and hydrolyzation. Kerke has launched a newly high-tech, lower-shearing, and low-temperature twin screw extruder for the PET process

TPU/TPO/EVA Sheet Production Line

Elastomer material sheet extrusion needs a special extruder design, Our Parallel Co-rotating twin screw extruder is designed for TPU/TPO/EVA sheet production with an output capacity from 300kg/h to 1000kg/h

Plastic Extruder Auxiliary Equipment

With our experience in compounding extruders, Kerke can provide the twin screw extruder auxiliary equipment to customers. Such as the high-speed mixer, the plastic granulator, the pulverizer, the extruder core parts, and the water chiller.

High-speed Mixer

As the core part of the compounding and masterbatch production process, the high-speed mixer is for premixing all raw materials, Our mixer volume from 5L to 2000L, high-speed mixer, and hot-cold double-stage mixer.

Plastic Pelletizer & Granulator

The plastic pelletizer machine is a very important part of the compounding extruder (spaghetti type), but how to choose a suitable plastic pelletizer machine is not easy, Kerke can provide the pelletizer machine from 1kg/h to 2000kg/h, we have the standard type and high standard type, the pellets size can be from 3mmx5mm to 0.5mmx0.5mm (micro pellets)

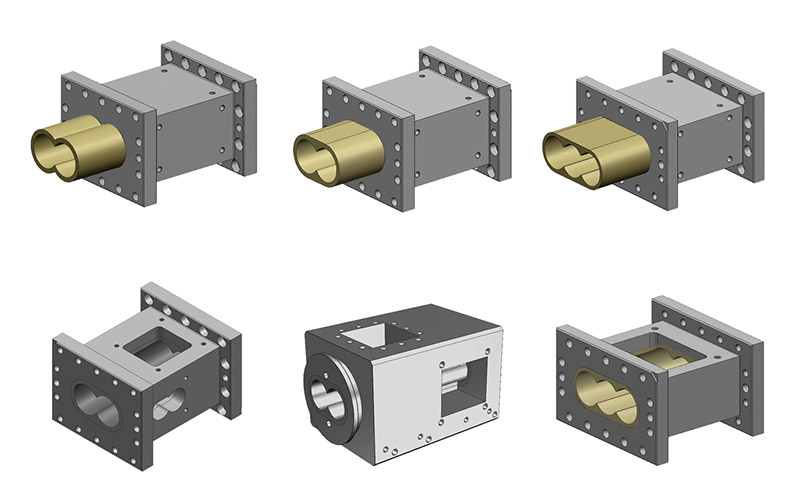

Extruder Parts

Kerke started from the extruder parts trade, then we have our factory to produce screw elements and sell to extruder factories, in 2009, we started to produce extruders by ourselves. Now many other manufacturers still buy core parts from outside, but we still insist on producing core parts by ourselves, because we can control the quality and send all parts to our customers fast. So you can trust Kerke always

Plastic Pulverizer / Mill Machine

Our pulverizer machine is designed for compounding and masterbatch making with an output capacity from 30kg/h to 500kg/h. Mainly materials

- PE Resin

- PP Resin

- PVC

Water Chiller

A water chiller is an essential part of the extrusion machine, Kerke can provide a high-quality water chiller at a good price. We have air cooled chiller and water cooled chiller

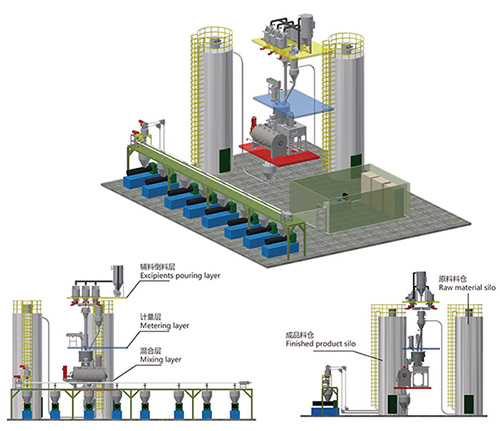

Automatic Weighing and Dosing System

Automatic Dosing & Weighing System plays an important role in the highly required application, there are many advantages of the dosing system such as saving labor, and time, control of your formula feeding accurately, etc. We can provide a suitable solution according to your requirement

PVC Automatic Weighing and Mixing System

The PVC additives auto weighing system – We developed this auto weighing system to instead of traditional old manual weighing. It could auto-weigh the additives for the pvc extrusion production, such as, stearic acid, wax, titanium dioxide, whitener, carbon black etc.

Gravimetric Feeder (Loss in Weight)

A gravimetric feeder, also known as a loss-in-weight feeder, is a self-calibrating dosing system that doses based on weight in speed. A volumetric feeder, on the other hand, does this based on volume in speed. In gravimetric dosing, the weight of the dosed additive is measured using a load cell that is the foundation of the entire system. Weight is calculated using loss-in-weight technology, which measures the reduced weight while dosing