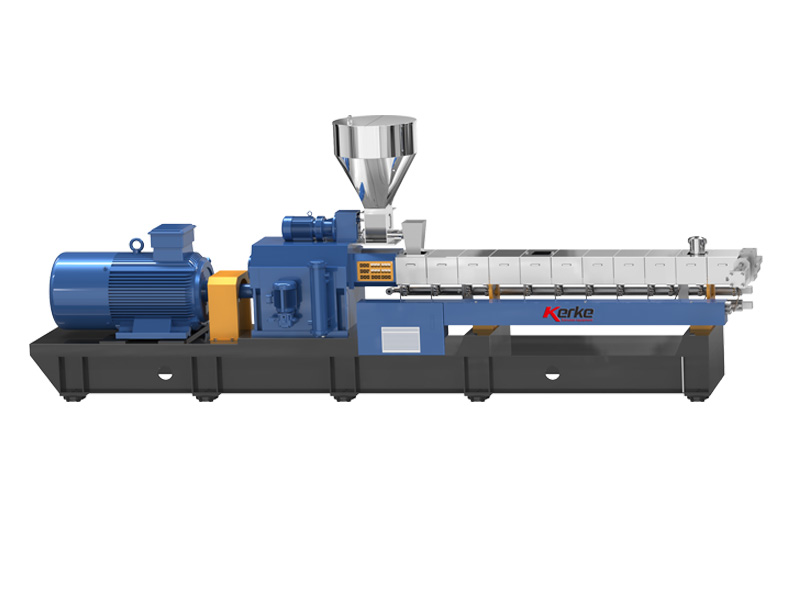

Parallel Twin Screw Extruder

Our Parallel Co-rotating twin screw extruder is designed for compounding and masterbatch making with an output capacity from 30kg/h to 4000kg/h.

- Color Masterbatch Filler Masterbatch

- Engineering Plastic Biodegradable Plastic

- TPU/EVA Elastomer HMMA/TVP Application

- others

Why should you choose Kerke twin screw extruder?

When considering an investment in industrial equipment, particularly in the realm of polymer processing, the choice of machinery can significantly impact the efficiency, quality, and profitability of your operations. Kerke’s twin-screw extruders stand out as an exemplary choice for several compelling reasons.

Advanced Technology and Innovation

Kerke is renowned for its commitment to incorporating the latest technological advancements into its twin-screw extruders. Their machines are designed to handle a wide range of materials, including but not limited to plastics, rubber, and food products. The company’s focus on continuous innovation ensures that their extruders not only meet current industry standards but also set new benchmarks for performance and reliability.

Superior Mixing and Homogenization

One of the primary advantages of Kerke’s twin-screw extruders is their exceptional mixing and homogenization capabilities. The co-rotating twin-screw design facilitates superior blending of materials, ensuring a consistent and uniform output. This is crucial for applications where the quality and consistency of the final product are paramount. The precise control over the mixing process also allows for the incorporation of additives and fillers with high efficiency.

Energy Efficiency and Cost-Effectiveness

Kerke’s extruders are engineered to be energy efficient, reducing operational costs and minimizing environmental impact. Their machines utilize advanced screw designs and optimized processing parameters to achieve high throughput rates while consuming less energy. This not only translates to lower energy bills but also aligns with sustainable manufacturing practices, making it an economically and environmentally sound choice.

Versatility and Customization

Kerke offers a wide range of twin-screw extruders that cater to various industrial needs. Whether you require a machine for basic extrusion or complex compounding tasks, Kerke provides customizable solutions tailored to your specific requirements. Their extruders can be configured with different screw elements, barrel designs, and auxiliary equipment to meet diverse production needs. This versatility ensures that you can adapt the machinery to various applications, thereby maximizing your investment.

Robust Construction and Durability

Durability is a critical factor in industrial machinery, and Kerke excels in this area. Their twin-screw extruders are constructed with high-quality materials and components, ensuring long-term reliability and reduced downtime. The robust construction of these machines means they can withstand the demanding conditions of continuous production, thereby ensuring consistent performance over an extended period.

Comprehensive Support and Service

Kerke is dedicated to providing exceptional customer service and support. From the initial consultation and installation to ongoing maintenance and technical assistance, the company ensures that their clients receive comprehensive support throughout the lifecycle of the extruder. This commitment to customer satisfaction helps in maintaining optimal machine performance and addressing any issues promptly, thereby minimizing disruption to production processes.

Choosing Kerke’s twin-screw extruders is a strategic decision that can significantly enhance your production capabilities. Their advanced technology, superior mixing capabilities, energy efficiency, versatility, robust construction, and exceptional customer support make them a standout choice in the market. Investing in a Kerke twin-screw extruder means investing in quality, reliability, and long-term success for your manufacturing operations.

Main technical parameter

Model | Screw Diameter | D/d | Maximum Speed | Motor | Torque | Output |

KTE-16 | 15.6 | 1.71 | 500 | 2.2 | 2X18 | 1~5 |

KTE-20 | 21.7 | 1.55 | 500 | 4 | 2X30 | 2~15 |

KTE-25D | 26 | 1.55 | 500 | 7.5~11 | 2X85 | 5~20 |

KTE-36B | 35.6 | 1.51 | 500~600 | 18.5~22 | 2X210 | 20~100 |

KTE-36D | 35.6 | 1.51 | 500~600 | 22~37 | 2X352 | 20~150 |

KTE-50B | 50.5 | 1.55 | 500~600 | 55~75 | 2X525 | 80~200 |

KTE-50D | 50.5 | 1.55 | 300~800 | 75~90 | 2X860 | 100~300 |

KTE-52B | 51.4 | 1.58 | 500~600 | 55~75 | 2X720 | 80~200 |

KTE-52D | 51.4 | 1.58 | 500~600 | 75~110 | 2X1050 | 100~400 |

KTE-65B | 62.4 | 1.55 | 500~600 | 90~110 | 2X860 | 200~450 |

KTE-65D | 62.4 | 1.55 | 300~800 | 132~160 | 2X1530 | 350~600 |

KTE-75B | 71 | 1.51 | 500~600 | 132~160 | 2X1530 | 300~800 |

KTE-75D | 71 | 1.51 | 300~800 | 200~315 | 2X2100 | 500~1000 |

KTE-85B | 85 | 1.54 | 500~600 | 220~315 | 2X2100 | 550~1000 |

KTE-95B | 93 | 1.52 | 500~600 | 250~315 | 2X3000 | 800~1500 |

KTE-95D | 93 | 1.52 | 500~800 | 315~500 | 2X4800 | 1000~2000 |

KTE-135B | 135 | 1.55 | 500~600 | 315~500 | 2X4800 | 1500~3000 |

KTE-135D | 135 | 1.55 | 500~800 | 500~1000 | 2X7800 | 1500~4000 |