Cutting System / Pelletizing System

Different material needs different cutting system, Kerke provides all kinds of cutting system, here is the explanation of each cutting system

1. Water Cooling Strands Cutting (Spaghetti type)

This is the common and frequently-used cutting type, the strands (spaghetti) come from the die head then into the water cooling tub, then the air blower to remove the water, then into the granulator. This cutting type is widely used in color masterbatch, engineering plastics

2. Air Cooling Strands Cutting (Spaghetti type)

This cutting type is for some materials that can not touch the water but can not use hot-face cutting types like biodegradable, PP calcium carbonate filler, etc.

3. Air Cooling Hot-face Cutting

This cutting type is for PE filler, WPC material, PVC, etc

4. Water-ring Hot-face Cutting

This cutting type is for material that can touch the water but not stick to the die head like the recycling PE, PE compounding, Hard shore EVA, etc. Material is cut at the die head and flows into the dehydrator system with water

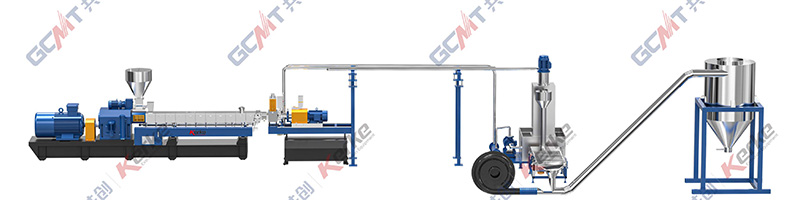

5. Underwater Pelletizing System

This is the best cutting system that can cut nearly all plastic materials (except materials that can not touch water). But this system price is high and needs the operator to have the experience, so now mainly used the applications that have to use the underwater cutting system like elastomers (TPU, TPR, TPE, EVA, etc)

Above are our main cutting systems for different materials, if you have any other ideas about the cutting system, we can discuss them together, send your special request