Plastic Extruder Auxiliary Equipment

With our experience in compounding extruders, Kerke can provide the twin screw extruder auxiliary equipment to customers. Such as the high-speed mixer, the plastic granulator, the pulverizer, the extruder core parts, and the water chiller.

High-speed Mixer

As the core part of the compounding and masterbatch production process, the high-speed mixer is for premixing all raw materials, Our mixer volume from 5L to 2000L, high-speed mixer, and hot-cold double-stage mixer.

Plastic Pelletizer & Granulator

The plastic pelletizer machine is a very important part of the compounding extruder (spaghetti type), but how to choose a suitable plastic pelletizer machine is not easy, Kerke can provide the pelletizer machine from 1kg/h to 2000kg/h, we have the standard type and high standard type, the pellets size can be from 3mmx5mm to 0.5mmx0.5mm (micro pellets)

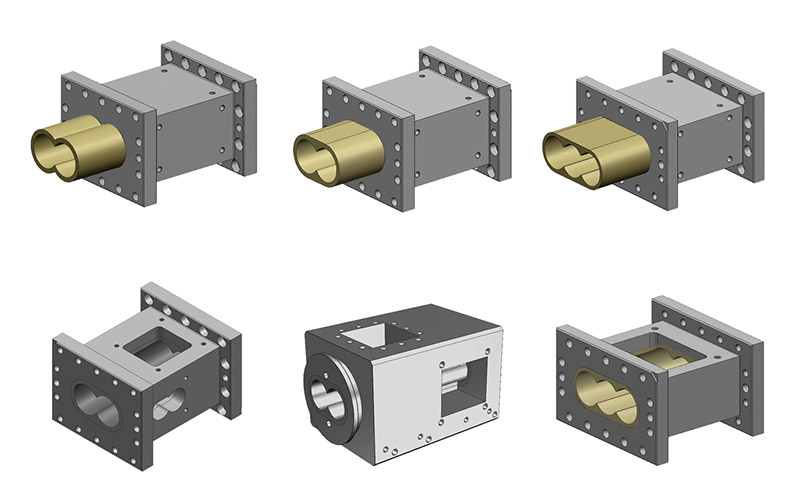

Extruder Parts

Kerke started from the extruder parts trade, then we have our factory to produce screw elements and sell to extruder factories, in 2009, we started to produce extruders by ourselves. Now many other manufacturers still buy core parts from outside, but we still insist on producing core parts by ourselves, because we can control the quality and send all parts to our customers fast. So you can trust Kerke always

Plastic Pulverizer / Mill Machine

Our pulverizer machine is designed for compounding and masterbatch making with an output capacity from 30kg/h to 500kg/h. Mainly materials

- PE Resin

- PP Resin

- PVC

Water Chiller

A water chiller is an essential part of the extrusion machine, Kerke can provide a high-quality water chiller at a good price. We have air cooled chiller and water cooled chiller