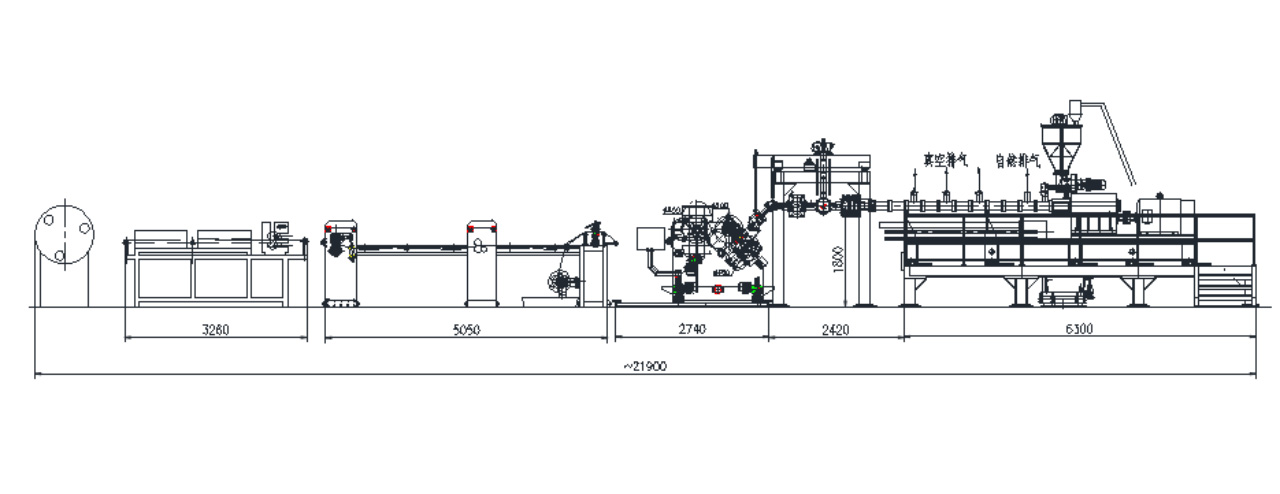

PET/R-PET Sheet Extrusion Line

Twin screw extruder has unique merits to the process of polyester resins. Polyester is very vulnerable to thermal decomposition and hydrolyzation. Kerke has launched a newly high-tech, lower-shearing, and low-temperature twin screw extruder for the PET process, which streamlined the process, and portrayed advantages in energy-saving and end product quality. As a result, the whole production cost has been contained

Advantages of Our PET /R-PET Sheet Extrusion Line

- Energy-saving: twin screw extruder direct extrusion technology eliminated the necessity of pre-drying of polyester, thus the electricity can be saved up to 40%

- Product quality: thanks to the high-torque, low-shearing, and low-temperature twin screw extruder, the lower process temperature can inhibit the negative effect caused by thermal decomposition demonstrably. Plus innovative high-efficiency vacuum system and the twin screw extrusion system can minimize hydrolyzation and oxidation as less as possible, which is harmful to polyester resins like PET/PC. Furthermore, the vacuum can remove some low molecular particles generated by the extrusion process; therefore the quality of final products has been raised

- Streamlined process flow: the pre-dry system has been removed from the process, and the whole process flow has been streamlined which can bring down the investment, operation, and production costs. In addition, the footprint, logistic and labor cost has been saved as well

- Wider tolerance of raw materials: the nature of self-wiping makes the twin screw extruder more tolerant with the shape and bulk density of the raw materials. No matter whether pellets, powder, flakes, film even yarn can be taken easily. Not only has the pre-dry process been eliminated, but the pelletizing process has been spared too

- Cost containment: each merit above mentioned can save cost directly and indirectly

Main technical parameter

Model | Screw Diameter | D/d | Maximum Speed | Motor | Output |

KTE-75 | 71 | 1.51 | 300 | 132 | 300~400 |

KTE-95 | 93 | 1.52 | 300 | 250 | 500~800 |

KTE-110 | 110 | 1.55 | 300 | 350 | 800~1200 |