kerke

-

MDPE Masterbatch

Read more: MDPE MasterbatchMDPE masterbatch is composed of excess chemical additives, carrier resins (such as MDPE), and dispersants. It usually contains components such as flame retardants, resins, and additives to endow plastic products with specific properties. MDPE masterbatch is widely used in injection molding, extrusion, blown film, drawing, foaming, coating and other process products. For example, it can…

-

PMMA Masterbatch

Read more: PMMA MasterbatchPMMA masterbatch is a kind of plastic masterbatch made of polymethyl methacrylate (PMMA) as the basic material. At present, there are many suppliers in the market providing PMMA masterbatch products, such as anti blue light masterbatch, anti-aging masterbatch, etc. These products come in different specifications, performance, and prices to meet the needs of different customers.…

-

PPO Masterbatch

Read more: PPO MasterbatchPPO masterbatch is a type of plastic masterbatch made from polyphenylene oxide (PPO) as the base material, which has various excellent properties and is widely used in multiple fields. PPO masterbatch can be mixed with other plastics such as ABS HDPE、PPS、PA、HIPS、 Glass fiber and other materials are blended and modified to further improve their performance…

-

Caco3 Filler Masterbatch

Read more: Caco3 Filler MasterbatchCaco3 filler masterbatch is a concentrated mixture containing calcium carbonate particles, which is mixed with a carrier and then cut into granules. The granules are white with a whiteness of over 98%. It is mainly composed of calcium carbonate filler, coupling agent, dispersant, and carrier resin. Among them, calcium carbonate mainly plays a role in…

-

PPS Masterbatch

Read more: PPS MasterbatchPPS masterbatch is an additive used for polyphenylene sulfide (PPS) plastics. PPS is used as a carrier resin, and various functional additives (such as conductive agents, flame retardants, reinforcing agents, etc.) and other necessary additives are added to produce a granular product through mixing, extrusion, granulation and other processes. Types PPS masterbatch, also known as…

-

ABS Masterbatch

Read more: ABS MasterbatchABS masterbatch is a granular product made by mixing ultrafine composite inorganic powder particles or functional additives with carrier resin, and extruding and granulating them through a twin-screw extruder. When manufacturing ABS masterbatch, the raw material is usually heated to a plastic state, then cast into a mold, cooled and solidified to form the masterbatch.…

-

PA Masterbatch

Read more: PA MasterbatchPA masterbatch is a granular product made from polyamide (PA) as a carrier, by adding various functional additives (such as flame retardants, antistatic agents, antibacterial agents, etc.) and other necessary additives, and through processes such as mixing, extrusion, and granulation. According to different functions, PA masterbatch can be divided into various types such as flame…

-

TPU Masterbatch

Read more: TPU MasterbatchTPU masterbatch is a new polymer material composed of a high proportion of pigments and thermoplastic polyurethane elastomers (TPU) that are well dispersed, extruded, and pelletized. The resin selected for TPU masterbatch has good wetting and dispersing effects on coloring agents, and has good compatibility with the colored material. TPU itself has excellent characteristics of…

-

PP Masterbatch

Read more: PP MasterbatchPP masterbatch, also known as polypropylene masterbatch, is a granular material made on the basis of polypropylene (PP) resin by adding various additives (such as pigments, fillers, plasticizers, antioxidants, etc.) and undergoing processes such as mixing and granulation. Classification of PP masterbatch PP masterbatch, also known as polypropylene masterbatch, can usually be classified according to…

-

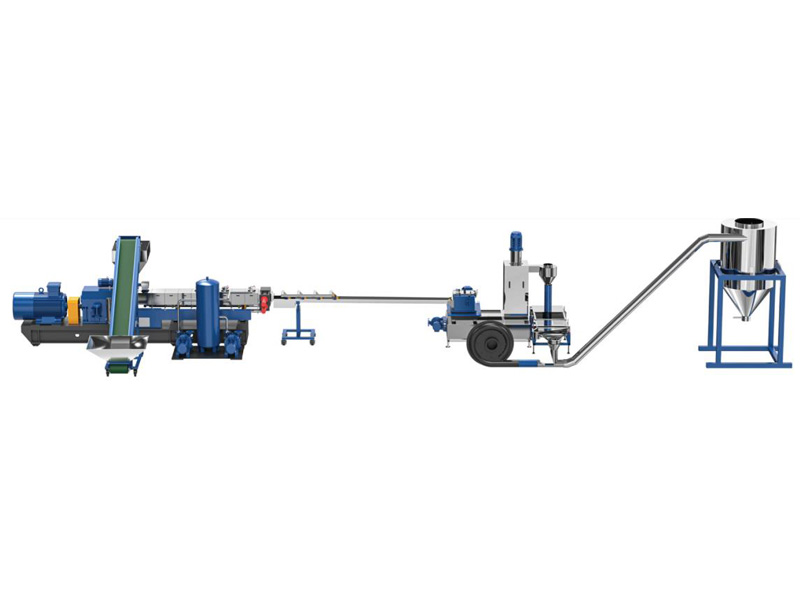

Cutting System / Pelletizing System

Read more: Cutting System / Pelletizing SystemDifferent material needs different cutting system, Kerke provides all kinds of cutting system, here is the explanation of each cutting system 1. Water Cooling Strands Cutting (Spaghetti type) This is the common and frequently-used cutting type, the strands (spaghetti) come from the die head then into the water cooling tub, then the air blower to…