kerke

-

PET Masterbatch

Read more: PET MasterbatchPET masterbatch is usually a milky white or light yellow granular material with high glossiness and transparency. Its density is about 1.38-1.41g/cm ³, with good dimensional stability and mechanical strength. At the same time, it has excellent chemical corrosion resistance and can resist the erosion of most acids, alkalis, and organic solvents. But in high…

-

PVC Masterbatch

Read more: PVC MasterbatchPVC masterbatch is a form of polyvinyl chloride (PVC), which is a granular product made by processing PVC resin as the matrix and adding various additives and additives. Usually white or slightly yellow particles, there are also other color particles made by adding color masterbatch according to demand. PVC masterbatch extruder Kerke’s masterbatch extruder can…

-

Polyethylene Film Masterbatch

Read more: Polyethylene Film MasterbatchPolyethylene film masterbatch refers to additive particles uniformly dispersed in polymers, such as flame retardants, Caco3 powder, etc. These additives can endow polyethylene film with specific properties. Polyethylene film masterbatch has broad application prospects in the plastic products industry and is an important raw material for manufacturing polyethylene film, with various types and excellent properties.…

-

Polyethylene Modified Masterbatch

Read more: Polyethylene Modified MasterbatchPolyethylene (PE) modified masterbatch refers to a polymer material with special properties prepared by adding a certain amount of modifiers (such as antibacterial agents, anti adhesive agents, flame retardants, etc.) and other additives to polyethylene resin through specific processing techniques (such as mixing, melting, extrusion, etc.). According to the different types of modifiers added, polyethylene…

-

Polyethylene Masterbatch (PE Masterbatch)

Read more: Polyethylene Masterbatch (PE Masterbatch)Polyethylene masterbatch is widely used in the production of various plastic products, such as plastic bags, plastic films, plastic pipes, etc. By adding different additives and fillers, polyethylene products with different properties and uses can be produced. The production of polyethylene masterbatch is a complex and delicate process that requires strict control over raw material…

-

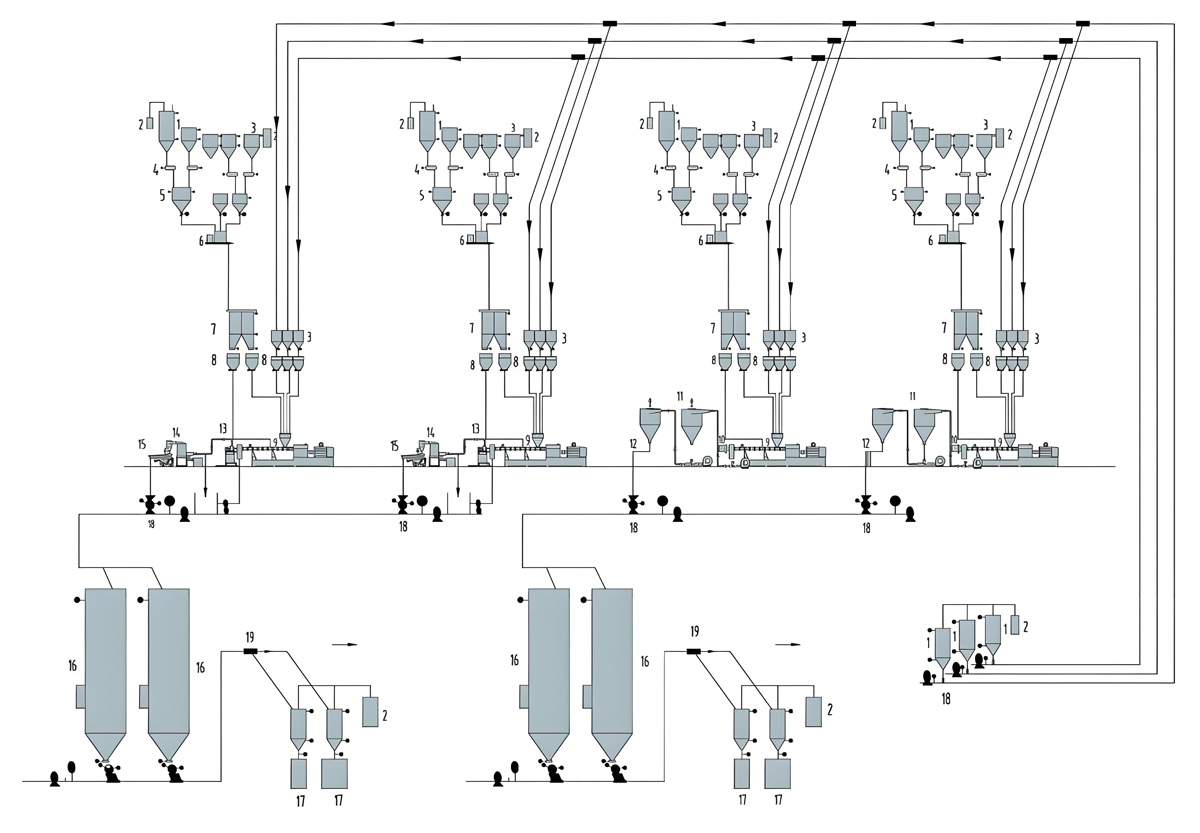

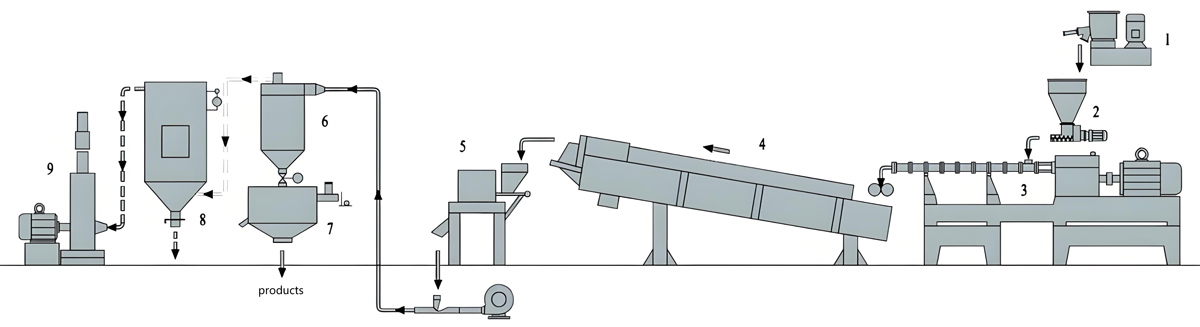

Fully-automatic Compounding System

Read more: Fully-automatic Compounding SystemFlow diagram for production of specially functional compounds using fully-automatic compounding system. Application The fuly-automatic compounding system includes material handiling, pneumatic conveying, preblending, multiple feeding, twin screw compounding dewatering /drying or cooling, product conveying, homogenization, weighing, and bagging.

-

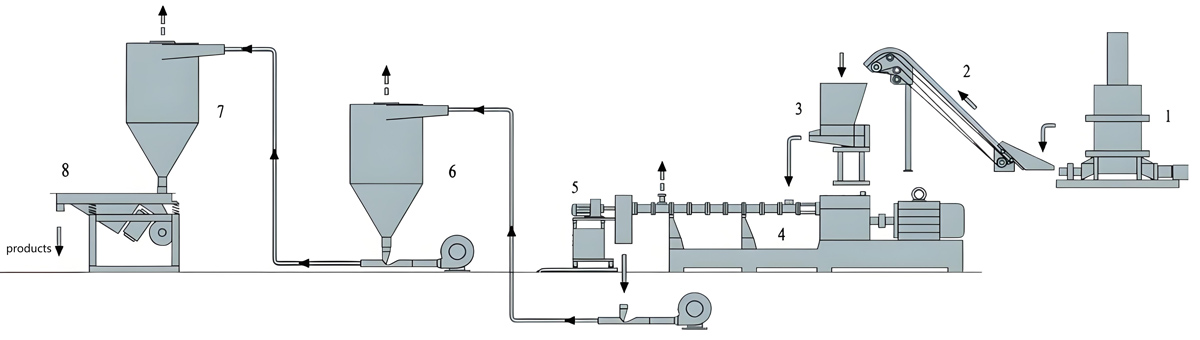

Kneader Downstream Continuous Extrusion Pelletizing Device

Read more: Kneader Downstream Continuous Extrusion Pelletizing DeviceApplication The advantages of internal mixer and extruder are reasonably combined, the process operation is flexible, the process is simple and practical, suitable for the transformation of old equipment and materials and processes that are difficult to fully continuous. It is suitable for high-filling operations of heat or shear-sensitive materials such as internal and external…

-

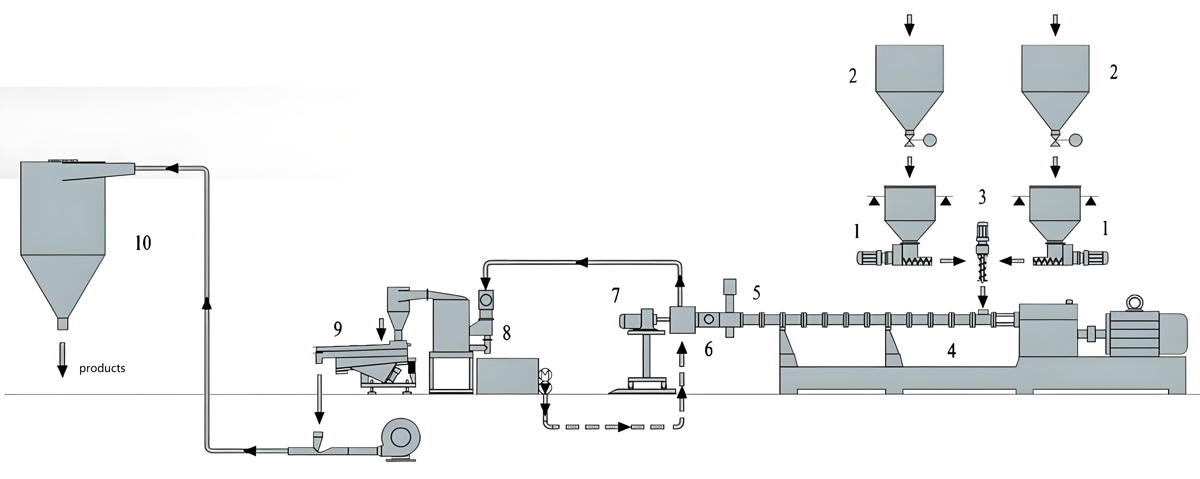

TPU Twin Screw Reactive Extrusion

Read more: TPU Twin Screw Reactive ExtrusionApplication Extensive heat and mass transfer, narrow residence time distribution, large surface to volume ratio, continuousoperation. ldear for high viscosity, high temperature reaction systems. Continuous polymerization or reactive extrusion lilke dynamic valcanization, crosslinking , grafting, and chain extension of PUR, PA, POM, PEI, PCPMMA, PBT, PPS, etc.

-

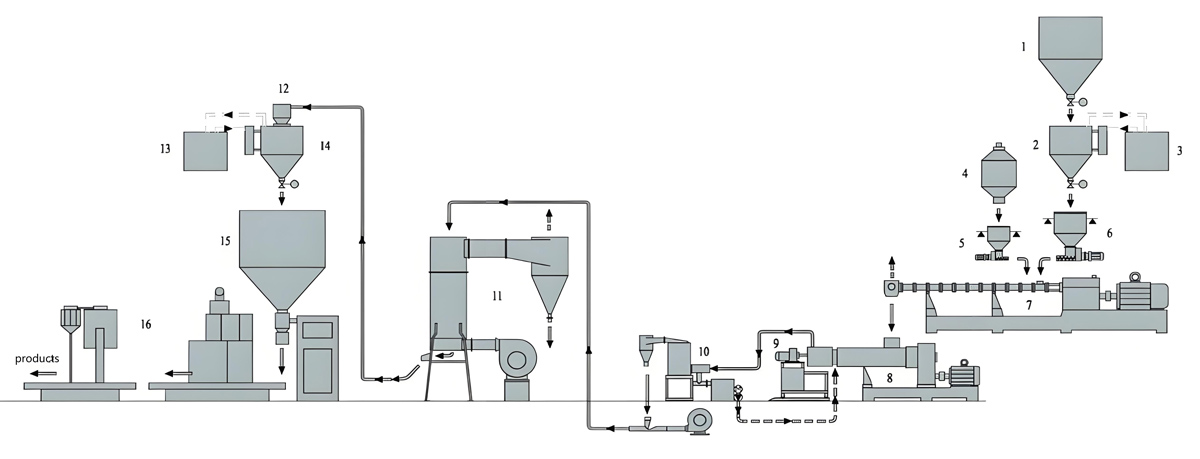

Tandem Line for Producing Crosslinkable Polyethylene Cable Compounds

Read more: Tandem Line for Producing Crosslinkable Polyethylene Cable CompoundsApplication This is another application of KTE/SE Tandem Line. Together with special low pressure and short channel die as wel as ec-centric die-face cutting technology, the tandem line is capable of effectively mixing/compounding PE resins, antioxidantsand peroxides etc. At a low temperature , to minimize premature crosslinking of polytheylene.

-

Thermoset Plastics and Powder Coating Production Line

Read more: Thermoset Plastics and Powder Coating Production LineApplication The excelent mixina canablty, self-wioind characteristics, and accurate temperature conttols of co-rotaind twin-screw extruder enable thorough mixing of materials inside the extruder and essentialy no-pressure discharging. This line is applicable to theproduction of polyester, epoxy, and acrylic based powder coating, phenolics, and epoxy sealing compounds.